Updates to Downtime Reason Management

Take control of your downtime tracking with full editing, archiving, and uptime labelling

Product Update (October 2025)

Managing downtime reasons just got a major upgrade. You can now edit, rename, and organise your downtime reasons without losing any historical data. Plus, we've introduced smart archiving and a powerful new feature that lets you label uptime periods with downtime reasons - perfect for tracking setup time and other processes that trigger false positives.

New features:

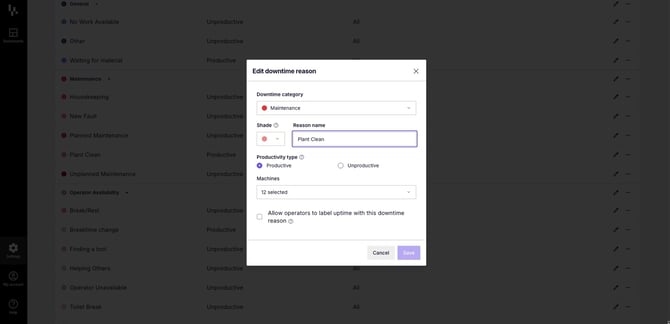

Edit and rename without losing historical data

Previously, changing a downtime reason meant it would affect all your historical data—making it risky to update or refine your tracking over time. That's no longer the case.

You can now freely edit and rename your downtime reasons, and your historical data will remain exactly as it was. This means you can:

- Fix typos or unclear naming without worry

- Refine your reason names as your processes evolve

- Reorganise your categories to match current operations

- Update productivity classifications as needed

Your past data stays intact, while your current setup reflects what you need today.

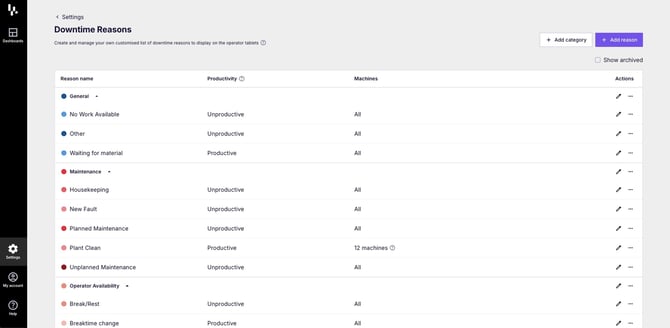

Archive instead of delete

We've introduced soft deletion through archiving. When you archive a downtime reason, it:

- Hides from operator tablets so it can't be selected going forward

- Hides from the management interface to keep things tidy

- Continues to appear in historical data exactly where it should

This solves the common problem of wanting to phase out old reasons while preserving your reporting accuracy. Simply toggle "Show archived" to view or restore any archived reasons whenever you need them.

Label uptime with downtime reasons ✨ New Feature ✨

This is a game-changer for manufacturers dealing with setup time, changeovers, and other productive activities that trigger machine uptime.

The challenge: Some processes—like machine setup or planned maintenance—cause your machine to register as running (uptime), when it's actually not producing parts. This skews your Availability and makes it hard to track true productive time.

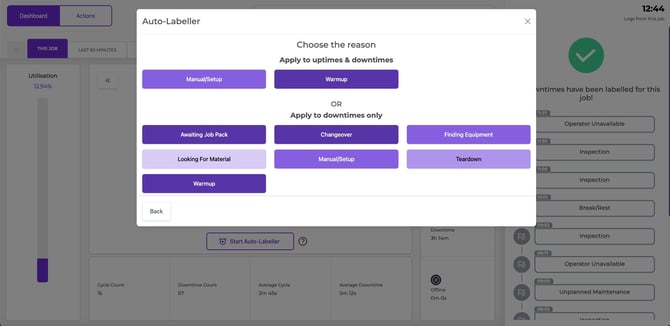

The solution: You can now enable specific downtime reasons to be used for labelling uptime periods. Here's how it works:

- Select which downtime reasons operators can use to reclassify uptime (e.g., "Setup", "Maintenance")

- When operators see uptime that wasn't productive, they can label it with these reasons

- Your data now accurately reflects what's actually happening on the shop floor

- Works seamlessly with Auto-Labeller (see below)

To enable this for a reason, simply check the box "Allow operators to label uptime with this downtime reason" when editing or creating a reason.

Powerful integration with Auto-Labeller

When combined with Auto-Labeller, the uptime labelling feature becomes even more powerful. You can set up rules to automatically classify all uptime and downtime accurately—no manual intervention needed.

For example, set Auto-Labeller to automatically label the next 90 minutes as "Setup" or "Warm up", ensuring your Availability calculations reflect reality from the start.

Got questions?

Don't hesitate to get in touch with our friendly support team by emailing support@fourjaw.com

.png?width=200&height=100&name=FJ%20white%20colour%20(400%20x%20200%20px).png)