How to use FourJaw Operate to log downtime

This article will walk you through how to log downtime and why that matters.

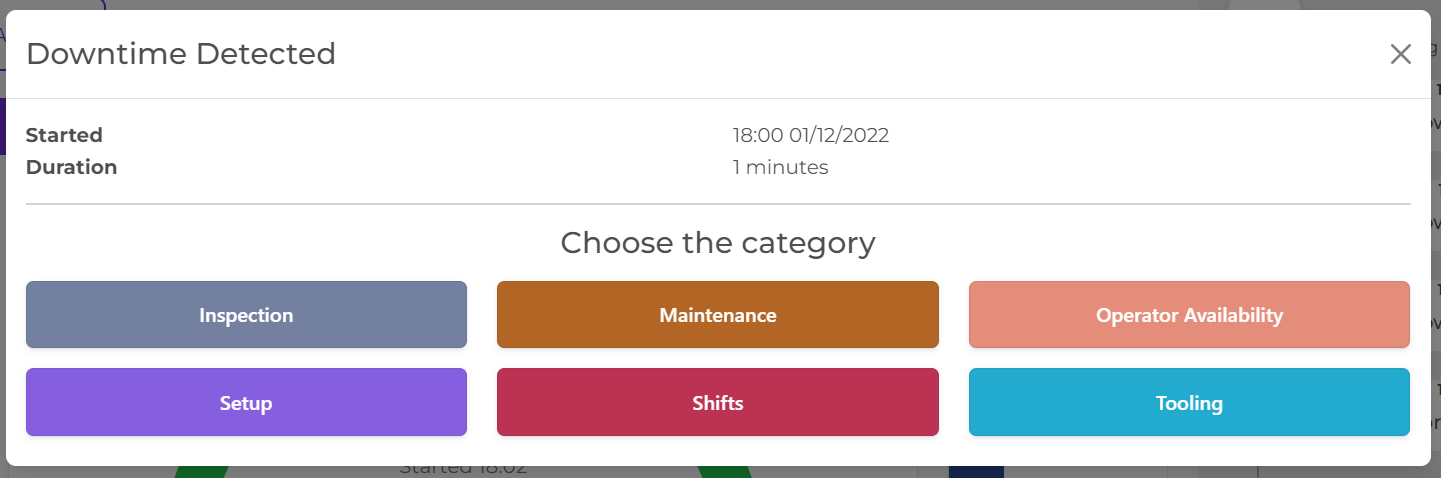

Downtime Detected

When the FourJaw MachineLink detects that there is a period of downtime (longer than the configurable period where no downtime reason is required, usually 5 minutes), this screen pops up on the tablet.

Operator Actions

- Choose the downtime category

- Choose the downtime reason

Missed Downtime

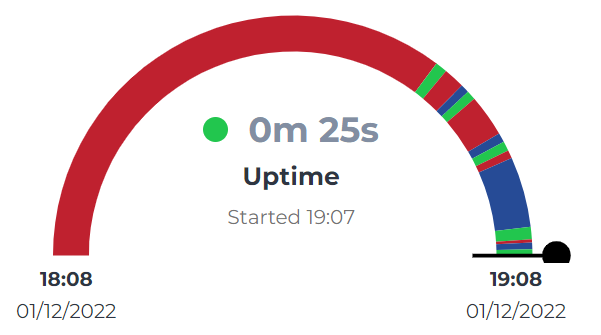

If an operator is not at the machine when the downtime is detected they can still see that it happened and log a reason.

They can see it on the main dial as a red or blue section.

They can see it in the Activity Log on the righthand side of the tablet.

Clicking on Downtime in the activity log opens up the screen where the operator can choose a category and reason.

What if a downtime reason changes?

In the scenario where you have logged a downtime (e.g., Set Up) and then the reason for the downtime changes (e.g., to Unplanned maintenance because a fault was found during set up), then you can start a new downtime on the actions page.

Why does it matter?

- It helps to make sure that problems in your cell are resolved, if you religiously log downtime this enables managers to make more informed decisions; which benefits you as it brings improvements to the shop floor.

- You, other operators and managers can all see the same data in real-time, this reduces blame.

- The data allows you to compare your machine’s performance today to previous timeframes and share best practice amongst shifts, this empowers you to always know how your machine is doing.

.png?width=200&height=100&name=FJ%20white%20colour%20(400%20x%20200%20px).png)