What is OEE and How is it Calculated in FourJaw

OEE (Overall Equipment Effectiveness) is the gold standard in productivity monitoring, taking into account Performance, Availability and Quality.

OEE identifies the percentage of manufacturing time that is productive. An OEE score of 100% means you are manufacturing only good parts (100% Quality), as fast as possible (100% Performance), with no downtime on the machine (100% Availability). It is used by many manufacturing companies as a key metric to understand the operational performance of a shop floor.

How Does FourJaw Calculate OEE?

OEE = Performance x Availability x Quality

OEE and Performance, Availability and Quality all start at 100% and are reduced when issues are logged.

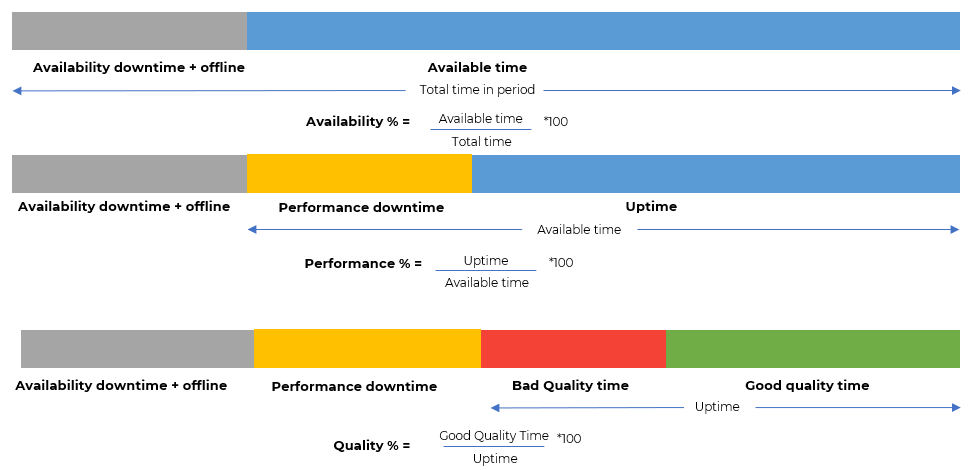

Availability %

Availability = ((Total time in the period – downtime logged to availability issues - Offline time) / Total time in the period) x 100

Performance %

Performance = ((Total time in the period – downtime logged to availability issues - offline time) - downtime logged to performance issues) / (Total time in the period – downtime logged to availability issues - offline time) x 100

Quality

Quality % = ((Uptime logged in time period - time labelled bad)/Uptime logged in time period) x 100

Define Downtime Reasons

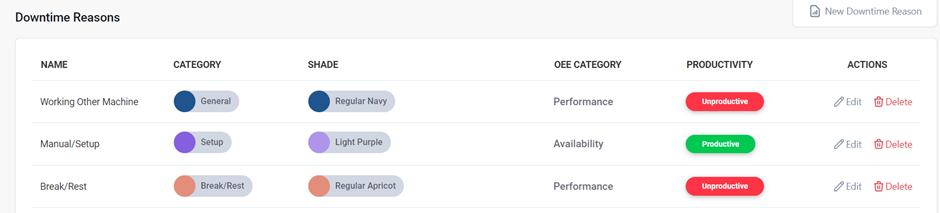

OEE in FourJaw tracks the performance and availability of your machine using the downtime reasons logged by machine operators. To do this, you need to choose an OEE category for each of your downtime reasons.

Anything that means your machine is not available to use because it is broken, undergoing maintenance or being programmed etc. is set to the downtime OEE category 'Availability'. Everything else is set to 'Performance'.

Examples of 'Availability' Downtime reasons include:

- Machine fault

- Tool broken

- Set Up

- Unplanned maintenance

Set Downtime Categories

In the settings menu, you can customise your downtime reasons and say whether you want them to apply to productive or unproductive downtime tracking. You can also set whether a downtime reason is related to the availability of the machine or performance for the purpose of tracking OEE.

FourJaw will configure the standard downtime reasons to work straight out of the box, however these can be changed and configured to suit your business needs at any point.

Logging Quality

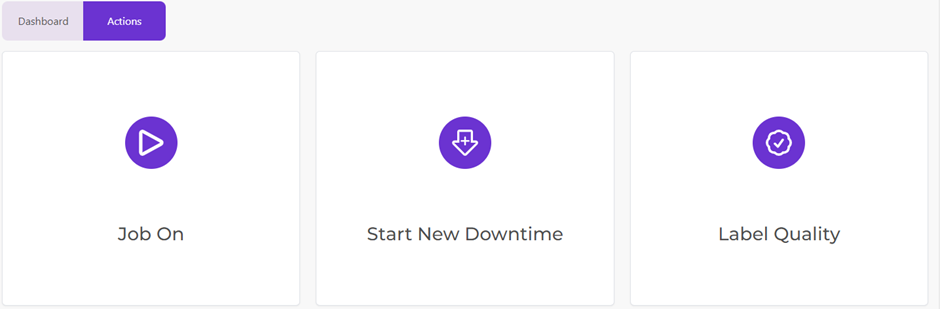

When a part is produced and known to be out of specification, the operator must log the period of time associated with this component (or the components that are incorrect) within the FourJaw platform.

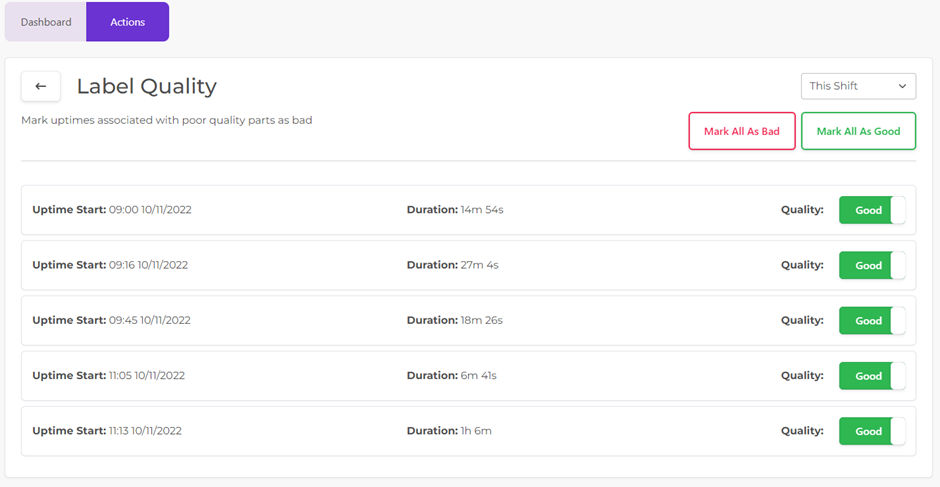

This is done using the actions button at the top of the screen and then selecting the “Label Quality” button from the view.

Using the time period drop-down menu to the right makes it possible to select a range of different time periods relating to the shift patterns to ensure parts that were complete and then found to be non-conforming at a later stage can be retrospectively marked as bad quality.

Updating these periods of time will affect the OEE figure on the main screen.

.png?width=200&height=100&name=FJ%20white%20colour%20(400%20x%20200%20px).png)